Dama Service CNC training

Technical training and support

Technical training is a crucial element in maximizing operational efficiency and the productivity of CNC machine tools. Dama Service CNC offers comprehensive and customized training programs, designed to meet the specific needs of your company.

Our training courses cover several areas of expertise:

- CNC Programming:

From basic programming to advanced techniques, our courses help create and optimize programs for CNC machines. In-depth topics include parameter and variable management, the use of fixed cycles, and the creation of custom macros to simplify and accelerate production processes. - Machine Operation:

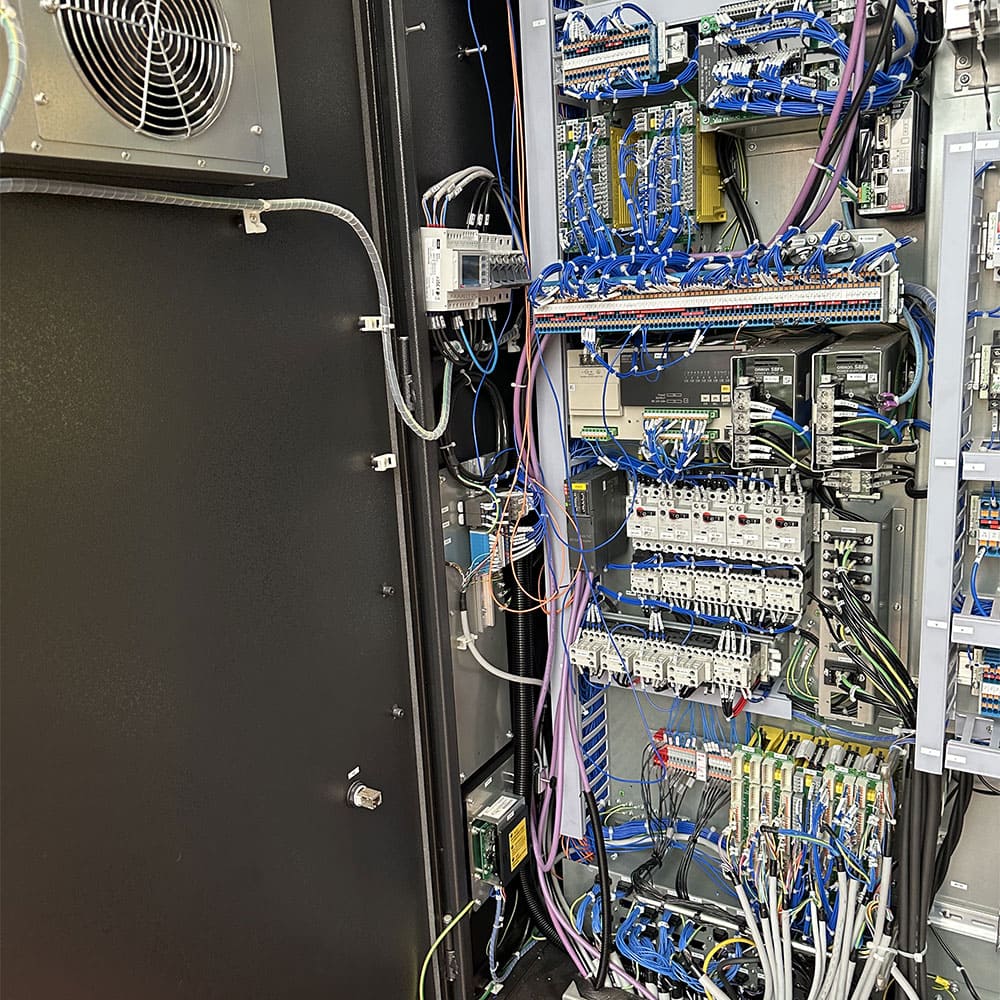

Proper machine operation is essential for ensuring quality results and maintaining high productivity. Our courses address all operations—from the basics to advanced setups, from tool management to safety procedures—to guarantee efficient and completely safe usage. - Specialized Maintenance:

Maintenance is a key element in preventing breakdowns and reducing downtime. We offer specialized training on diagnostic techniques and troubleshooting, PMC (Programmable Machine Control) analysis, backup and recovery procedures, as well as preventive maintenance strategies to maximize your machines’ reliability. - Customized Training:

Programs are tailored to your specific needs to maximize the effectiveness of learning. - Hands-on Experience on Real Machines:

Direct application of the acquired knowledge allows for rapid and tangible consolidation of skills. - Dedicated Operating Procedures:

During the course, we develop personalized work methodologies to optimize your business processes. - Complete Technical Materials:

We provide detailed documentation to support your daily operations even after the training. - Certificate of Participation:

At the end of the course, each participant will receive a certificate attesting to the skills acquired.

Advanced training for maintenance and troubleshooting

Efficient maintenance is the cornerstone of uninterrupted production. For this reason, we offer advanced courses dedicated to troubleshooting and problem-solving, with a focus on:

- Systematic troubleshooting methodologies: learning to quickly identify the root causes of issues in order to minimize machine downtime.

- Interpretation of alarms and error messages: understanding and effectively resolving errors to prevent production slowdowns.

- In-depth analysis of PMC systems: a detailed study of Programmable Machine Control for advanced machine management.

- Backup techniques and machine data management: strategies for protecting and restoring essential data, ensuring operational continuity.

- Development of customized maintenance procedures: creating targeted intervention plans to prevent failures and optimize performance.

Flexible delivery modes

We know how important it is to adapt training to business dynamics. For this reason, our courses can be delivered directly at your premises to minimize operational interruptions, in a mixed theoretical-practical mode for balanced learning between fundamental concepts and practical exercises, or with personalized sessions, both individual and group, to meet various training needs.

What will the participants be able to do at the end of the course?

Thanks to our training programs, your team will acquire the necessary skills to operate autonomously on CNC machines, manage emergency situations, reducing the risk of breakdowns and optimizing intervention times, implement preventive maintenance procedures, and finally optimize production processes, thereby improving the quality and competitiveness of the company.

Investing in training means investing in the future of your business. Contact us to design a tailor-made training program that meets your needs and brings concrete value to your production.

Why choose our courses?

With our courses, we offer:

Tailor-made training

Customized programs to develop specific skills and improve operational efficiency.

Practical learning

Exercises on real machines for the immediate application of the acquired knowledge.

Advanced maintenance

Troubleshooting techniques and preventive management to minimize machine downtime.

Flexibility and support

On-site courses, theoretical-practical or individual, with documentation and a final certificate.

Request information

Maximize the efficiency of your CNC with the right training! Fill out the form to learn about our technical courses and improve productivity and performance.