Case History

Restoration of C-Axis on WASINO Machine

The customer requested a technical intervention due to an anomaly detected on the C-axis of the WASINO machine, specifically related to a malfunction in the axis locking system.

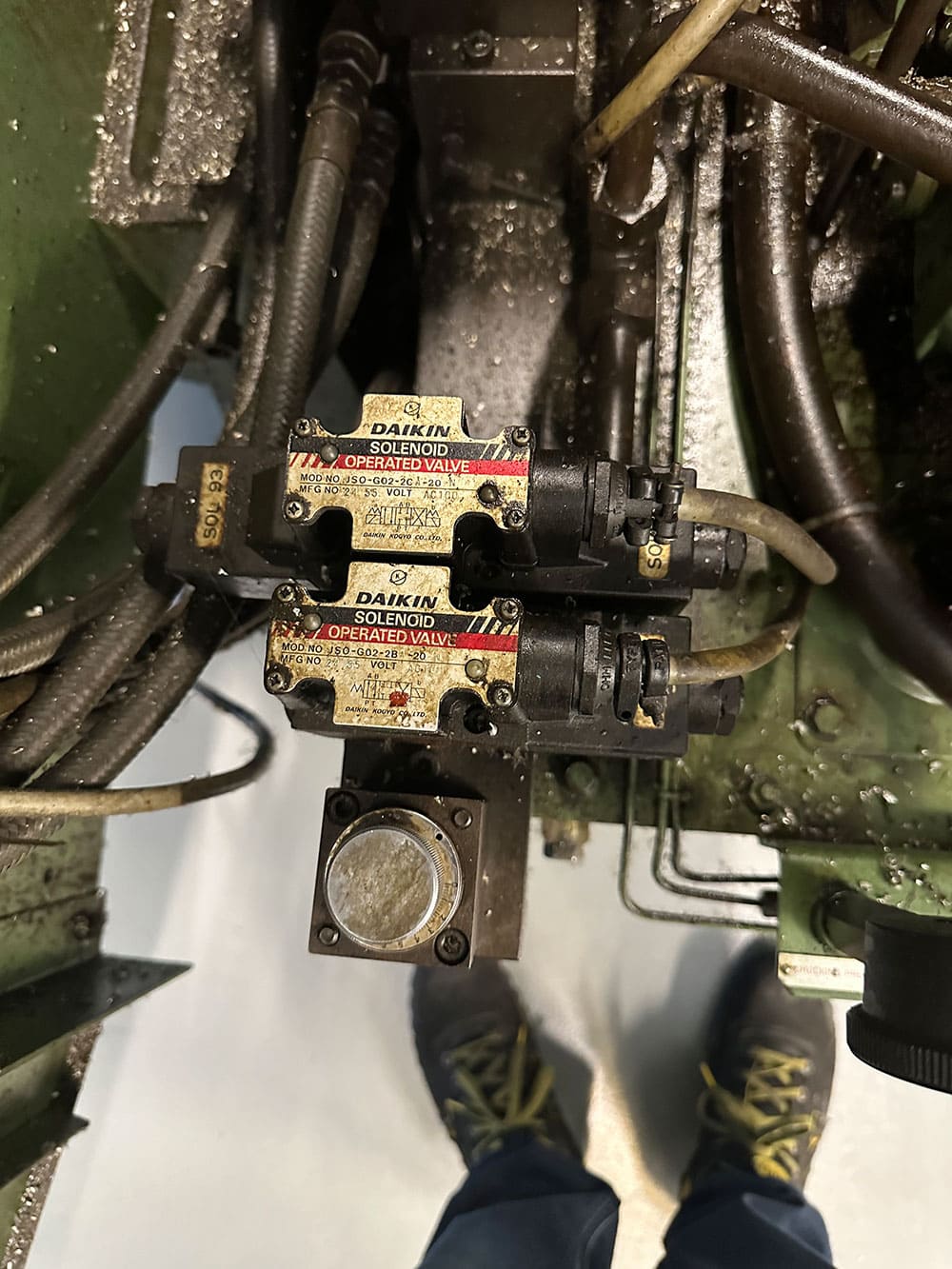

During the intervention, a thorough system analysis was conducted, including verification of the proper functioning of relays M54 and M55, as well as a check of control valves SOL54 and SOL55. Additionally, a manual inspection of the axis movement system was carried out to identify any anomalies.

Performed Intervention:

- Disassembly and inspection of the control valves

- Identification of a mechanical blockage on the SOL55 coil shaft

- Thorough cleaning of the shaft and valve

The intervention enabled the complete restoration of the machine’s functionality, thanks to a meticulous cleaning of the mechanical components, followed by a post-intervention functional check. Finally, a full test was conducted under operating conditions to ensure everything was working perfectly.

Result:

The machine was successfully returned to production without any further alarms or anomalies in the operation of the C-axis.

This case highlights the importance of regular maintenance of mechanical components, which is essential for preventing failures. It also underscores the need for a methodical approach in problem diagnosis to quickly identify the root causes. Finally, it demonstrates the effectiveness of targeted solutions based on a thorough technical analysis to achieve a definitive resolution.

Request information

For more information about our services or to request assistance, we invite you to contact us.

You will receive a prompt response from one of our experts.