Case History

Multiple Intervention on Makino V55

Initial solution:

The customer reported an abnormal noise coming from the spindle coolant recirculation pump on a Makino V55 machine with a Fanuc CNC.

Diagnosis:

During the intervention, several issues were detected:

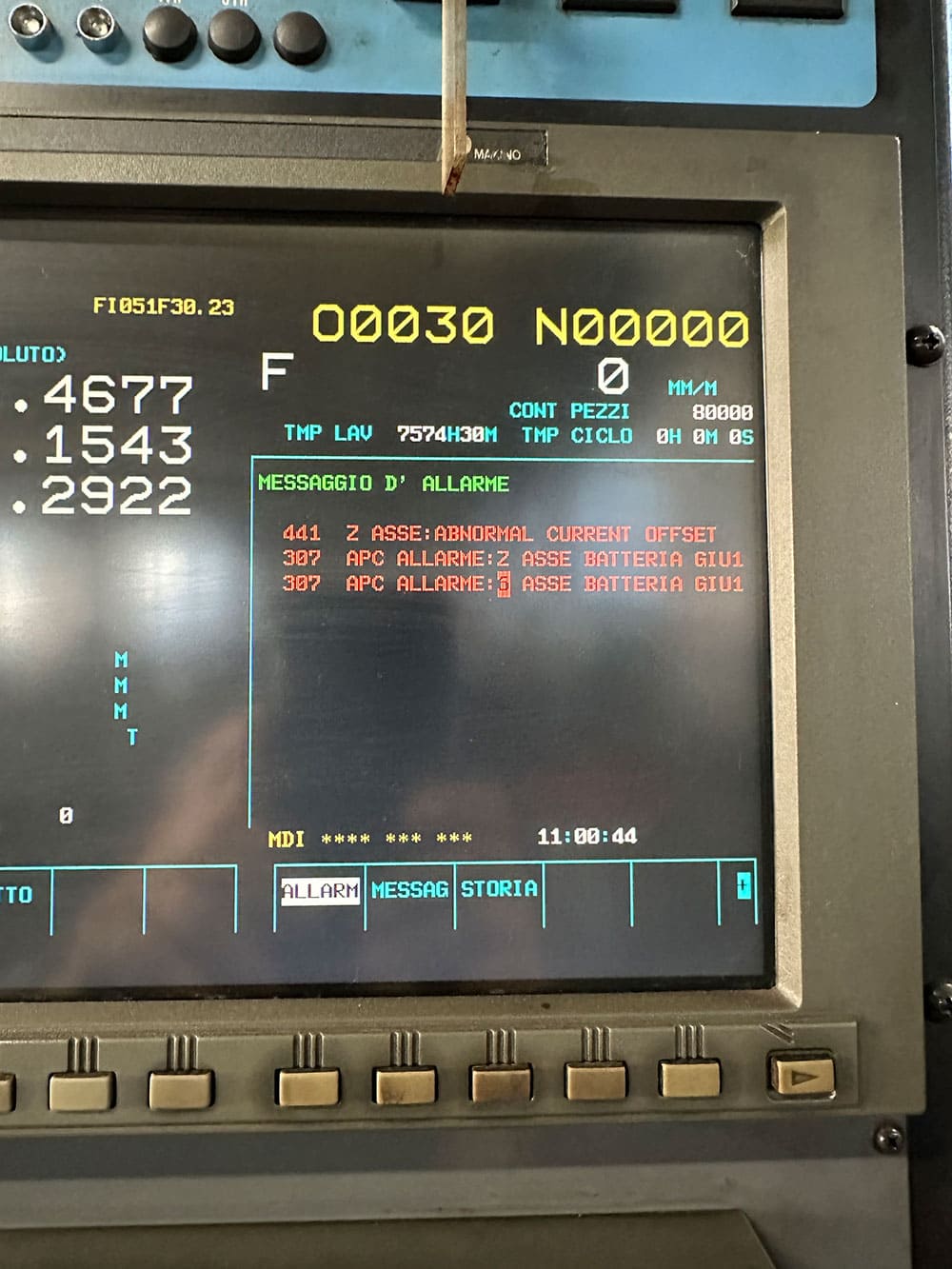

- Alarm 441 upon machine startup

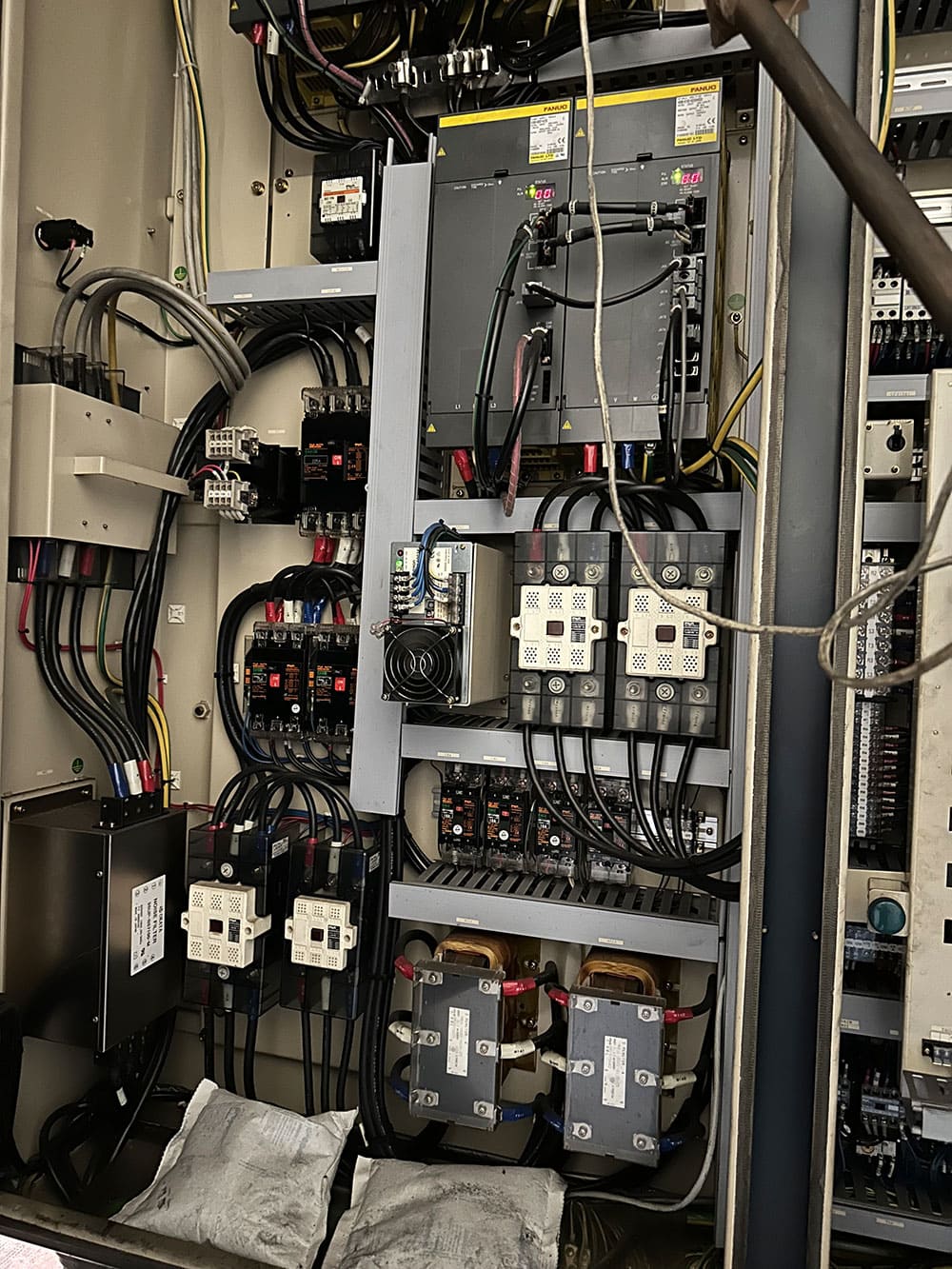

- Malfunction in the system drive

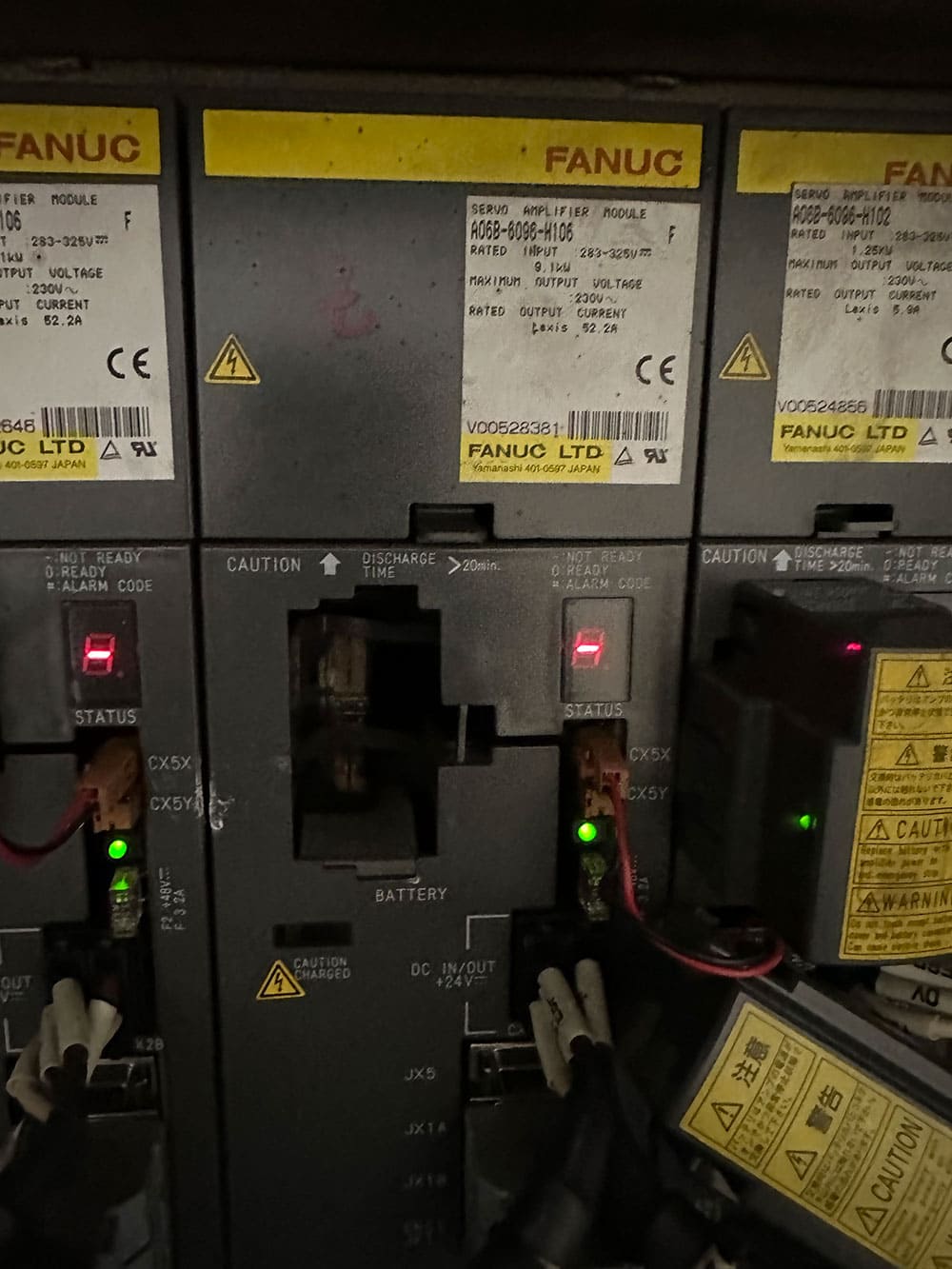

- Low battery on the Z-axis and the tool magazine

- Abnormal noise coming from the recirculation pump

Performed Interventions:

- Replacement of the batteries on the Z-axis while the machine was powered to preserve references

- Thorough inspection and cleaning of the recirculation pump

- Assessment of the drive system to identify any damage or wear

Solution:

We adopted a three-phase strategy:

- Immediate solution: cleaning the pump to reduce noise

- Planning the complete replacement of the pump

- Implementing preventive measures to protect the drive system

In agreement with the customer, several steps were established to ensure the proper functioning of the machine. It was decided to keep the machine powered on at all times to preserve the drive system and prevent unexpected downtime. Additionally, the installation of the new pump was scheduled for a future intervention to complete the necessary upgrade.

This intervention highlighted the importance of a thorough diagnostic analysis, essential for precisely identifying all related issues. It also emphasized the need to provide both temporary and permanent solutions based on the customer's specific requirements. Finally, it reinforced the value of preventive maintenance, which remains a crucial tool in avoiding unexpected failures and machine stoppages.

Request information

For more information about our services or to request assistance, we invite you to contact us.

You will receive a prompt response from one of our experts.